Bizarre Offshore Accidents And How To Avoid Them: 10 Essential Tips

Henry Bassey. Published May 2022.

- February 2022, Pemex reportedly suffered a third major fire in offshore facilities in the space of 13 months

- In February 2022 three dead, and four still missing after an FPSO explosion in Nigeria

- March 2022 OSV Captain's Blunders Led to Collision with US Coast Guard Cutter

If you are an ardent follower of oil and gas news or work in the sector, you are no stranger to the terrors of the offshore. The events described above are merely the highlights of recent happenings. We've had worse since offshore oil and gas drilling began.

Working on a drilling rig far from shore is frequently monotonous and routine until something goes wrong. Being stranded at sea during an explosion is a terrifying scenario; add fire, and you have the Deepwater Horizon disaster. Even if there is no fire, a gas leak on the seafloor can cause the rig to become unstable when the buoyancy of the water changes. When a well blows up on land, the crew and support staff are expected to evacuate to a predetermined area to assess the situation and count heads. A land-based emergency can immediately mobilize emergency responders. While land blowouts can still be fatal, the risks at sea are compounded.

Many old rig workers have lost fingers and toes. Throwing a chain around the pipe when connecting can cause digits to be lost, as can crushing digits while racking the pipe and activating power tongs. Slips and falls cause the majority of injuries or incorrect body positioning. Leaks, malfunctioning equipment, and smoking have all contributed to the deaths of workers. People who have never seen a well being drilled cannot understand the magnitude and weight of the supplies required. Even with tight safety requirements, it is clear that a human is extremely vulnerable under the shadow of so much heavy iron.

Regular Offshore Accidents

Offshore accidents and maritime mishaps come in a variety of forms. Lambert Zainey gathered at least seven. These are some examples:

1. Slip & Fall

Working on ship decks and oil rigs can be dangerous, especially in poor weather. Wet surfaces frequently cause workers to slip and fall, resulting in catastrophic harm. Other common accidents include falls from corroded walkways, stairwells with faulty welds, and falls from ladders or ledges without handrails.

2. Exposure to Chemical

Contact with hazardous materials might result in exposure injuries offshore. Workers who are exposed to these compounds through inhalation or direct contact can suffer substantial long-term consequences. Although safety precautions and protective equipment should be supplied, this is not always the case. Even if the proper equipment is given, equipment malfunction and the negligence of other workers can put you in danger of injury.

3. Failure and malfunction of equipment

Many offshore injuries and marine mishaps are caused by faulty or inadequate equipment. When equipment is not properly maintained or is not fit for the job at hand, it can cause serious injury to individuals operating the equipment as well as others working in its vicinity. Mechanical failures can also be linked to flaws in design and production. It is your employer's responsibility to offer safe and adequate equipment that is in good operating order. When you are hurt because your employer failed to take reasonable precautions, they are liable for your injuries.

4. Explosion And Fire

Offshore rigs, platforms, and boats, as well as inland tugs and barges, are constantly surrounded by combustible materials. Fires and/or explosions can occur when ventilation systems fail, fuel is improperly stored, vessels collide with or strike underwater obstructions, and in a variety of other situations. These events can result in devastating and frequently deadly injuries. The mechanism of how these catastrophes occurred and who is to blame necessitates a considerable understanding of marine law and the maritime industry, but it also frequently necessitates a solid technical background in science and engineering to analyze the cause adequately.

5. Objects Falling

One of the most prevalent types of offshore accidents in the marine sector is being struck by a falling or flying object, particularly on oil rigs, drillships, crane barges, and any multi-level vessel, the majority of which are unavoidable. Heavy machinery and support structures that become unsecured or are not properly secured have the potential to injure anyone on deck.

6. Weather Conditions

Injuries caused by exposure can also be linked to the harsh weather conditions that offshore workers face. Workers frequently work long hours in hot weather, which can lead to dehydration and heatstroke. Offshore employment can be just as dangerous in the winter, especially if a worker falls overboard into freezing cold water.

7. Inadequate Safety and Training

When businesses fail to offer proper training and safety equipment, workers are frequently hurt aboard. If you were hurt while working with equipment that you were not adequately trained on, or because safety precautions were not followed, your employer may be liable.

10 Ways to Avoid Injuries and Fatalities on Your Offshore Oil Rig

Oil rig injuries and fatalities will continue to occur, whether as a result of exposure to dangerous chemicals, falls, wellsite fires, explosions, or contact with equipment. Keystone Energy Tools outlined seven strategies to avoid them.

1. Develop a Safety-First Mentality

Ensuring workplace safety, particularly on oil rigs, must be a top concern that encompasses the thinking, attitude, and behavior of all workers, supervisors, and management.

As a result, it's in the operator’s best interest to educate everyone on the rig — both employees and subcontractors — about the significance of maintaining a safe work environment, which includes adhering to all safety rules and regulations and remaining vigilant to potential risks. It is also critical to remain informed of the whereabouts of all equipment required in the event of an emergency, such as fire fighting equipment.

Leadership that "walks the talk" is always beneficial in setting a safety norm. Workers will follow management's lead if it commits to safety. Workers will not buy in, however, if they do not see their superiors following policies and procedures.

2. Necessitate Orientation

Before being allowed on the rig floor, all new and transferred rig personnel need to go through a mandated orientation, such as SafeGulf or IADC RigPass. Such orientation helps employees and contractors get familiar with corporate and rig operational regulations, expectations, and Jobsite restrictions, therefore providing a safer work environment.

3. Consistently Train Employees

Following orientation comes training, which is a continuous process rather than a one-time event. It includes training on the machines and equipment used, as well as safety protocols. Consistent employee training indicates your commitment to safety and is another method to establish a safety-first culture.

4. Put On The Necessary Personal Protective Equipment

Personal protective equipment (PPE) such as safety glasses, hard hats, gloves, steel-toed boots, respirators, and fire-resistant clothes are required at all locations. However, this does not imply that all rig employees wear them.

A reasonable rule of thumb is that if you are not wearing the proper PPE, you are not permitted on site. Quality protective equipment is critical for avoiding injury. Wearing the equipment and not needing it is preferable to not wearing it and wishing you had.

5. Establish a Positive Reporting Process

Building a safety-first culture is easier when employees feel free to report concerns and are confident that management will take them seriously. Instead of reacting adversely (or even punitively) to employees who report possible hazards, recognize and promote their efforts.

When a potential safety concern is found, the reporting process should include the ability to halt operations. While it is rarely popular to stop work, a safety-first approach means that safeguarding someone from a potentially life-threatening scenario always takes precedence over output.

6. Create a Trusted and Respected Community

Humanity should always be present in safety training. This includes making it easier for employees to get to know one another. This will foster a sense of community, trust, and mutual respect. As workers develop personal ties, it stands to reason that they will look out for each other's best interests and be more ready to ask for help, follow rules, and seek advice when making decisions — all of which lead to increased overall safety.

7. Regularly Communicate Safety

Daily, weekly, and monthly safety meetings are an effective method to create a safety mindset and entrenched culture among employees. Instead of lecturing, employ interactive small group conversations to engage everyone and offer time for questions. Other methods of communicating safety include making safety policies available online and in print, as well as using your intranet to share best practices, updates, and news.

8. Inform Subcontractors

Everyone on the rig, including subcontractors, should prioritize safety. Choose only those whose safety record demonstrates that priority and refuse to invite anyone else on the rig who does not. Give them the same orientation and training that you would give to your workers.

9. Perform Routine Housekeeping

Keep superfluous things off the floors, passageways, and workspaces to avoid trips, falls, and collisions. Clean up any drilling fluids that may have accumulated on the rig floor during pipe handling activities, and post signage directing workers to emergency and safety equipment to battle dangers as soon as possible.

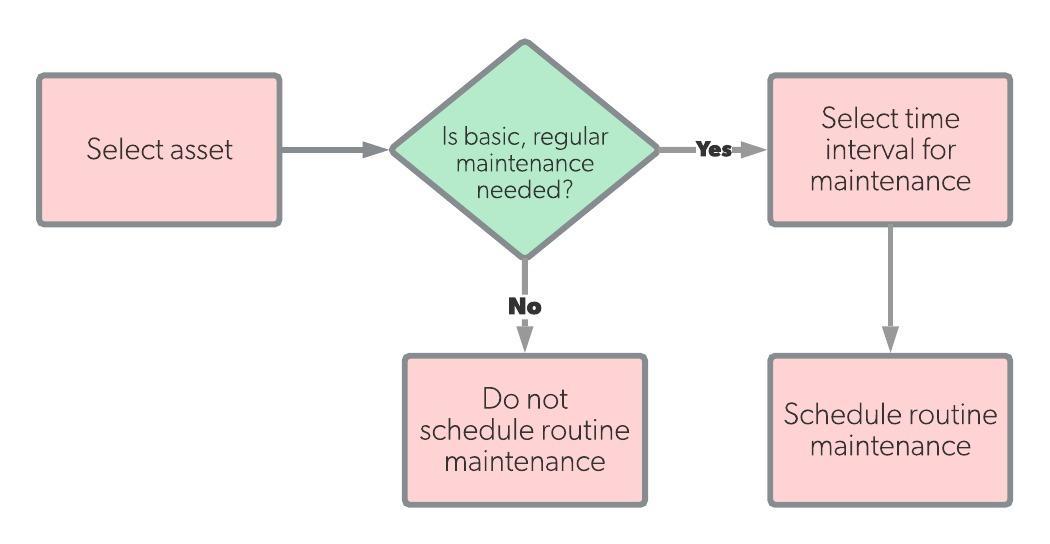

10. Keep Machinery in Good Condition

Maintain machinery on a regular basis to avoid premature failure, which could pose potential hazards, and then repair or replace damaged or malfunctioning parts and equipment as soon as possible.

Putting workers in danger because of a worn-out part that could fail at any time is reckless and unnecessary. Maintaining the equipment's integrity ensures a safer working environment. (Another way to develop a safety-first culture is to implement a mechanical integrity program that includes inspection, testing, and quality assurance in accordance with BSEE SEMS II (30 CFR 250.1916). Ensure that all equipment complies with industry standards (such as API, ABS, or DNV) and is kept in good working order.

Conclusion

Every industry involves some kind of risk, but none more so than the oil and gas industry. Taking safety seriously, especially on oil rigs that are frequently located hundreds of miles offshore, is no easy task, especially given the potential threats of offshore fires and dangerous chemicals.

Manup is the only workforce management platform that has in-app operational and HSE data capture forms which alter the game in terms of safety excellence, operational efficiencies, etc. Digitized safety and operational forms mean data sharing is instant which translates to reduced errors, improved analysis, and decision making as well as cuts HSE data capture and reporting time by as much as two-thirds. Furthermore, improved audit trails and on-demand access to safety stats protect against potential regulatory fines for non-compliance.

Don't wait for an injury or death to occur before taking steps to prevent accidents and fires; instead, be proactive. Use these ten suggestions to make "safety first, job second" a rallying cry that all of your employees and subcontractors will joyfully echo.

Other Publications

- Expert Opinions: Essential Metrics For Improved Hiring In The Oil & Energy Industry

- Super-Easy Way To Land A Drone Operator Job in the Oil and Gas Industry

- Learn These Software Packages To Succeed in the Oil & Energy Sector

- Top 8 Trends In The Oil & Gas Industry To Watch Out In 2022

- How Long Do You Think the Oil & Gas Industry Will Last?

- The Best MWD Engineers to Hire for Your Projects

- A Hustler's Guide to Starting A Career in the Energy Industry